Running a mining operation in South Africa comes with unique challenges. From heavy-duty transport to ensuring safe handling of powders and minerals, your packaging solutions need to be reliable, compliant, and cost-effective. That’s where Welpac, a trusted South African packaging company established in 1988, comes in. With over 25 years of experience, Welpac provides FIBC bulk bags, polypropylene bags, and other industrial packaging solutions designed to meet the demands of the mining sector.

Whether you need bulk bags for sale in Gauteng or a trusted bulk bag supplier for high-capacity mining loads, this guide covers everything you need to know about FIBCs in mining for 2025.

Understanding Bulk Bags (FIBCs) in the Mining Industry

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, are engineered to transport and store large quantities of mining materials efficiently and safely. Here’s what you need to know:

- What is a bulk bag?

A fibc bag is a heavy-duty woven container made from polypropylene (PP) or other durable polymers. Designed to carry up to 2,500kg SWL (safe working load) in mining applications, these bags are essential for safe transport and handling of minerals, powders, and aggregates. - Materials used:

Common materials include polypropylene bulk bags, PP woven bags, trunel bags, and FIBC bulk bags with inner liners for additional protection. These materials are chosen for durability, UV resistance, and heavy-duty handling capabilities. - Weight capacity & SWL:

Each fibc bag rated for mining is tested for its safe working load (SWL). The safety factor—typically 5:1 for mining-grade FIBCs—ensures the bag can withstand five times its SWL, reducing the risk of rupture during loading and unloading. - Top lift tests & UV protection:

Mining operations often expose bulk bags to harsh conditions. Top lift tests guarantee the strength and reliability of lifting loops, while UV treatment extends bag longevity under sunlight exposure. - Welpac highlight:

High-quality FIBC bags from Welpac are designed and tested for maximum weight capacity, with rigorous quality control measures ensuring each bag meets safety standards.

Mining Material Classification & Bulk Bag Types

FIBCs are classified into four types based on the materials they carry and their anti-static properties:

- Type A:

Non-conductive bulk bags for dry, non-explosive materials. No anti-static protection required. - Type B:

Suitable for fine powders that could create dust clouds. Conductivity requirements prevent electrostatic charges. - Type C:

Designed for explosive or combustible materials. Requires grounding during transport to prevent sparks. - Type D:

Offers the highest anti-static protection for highly combustible environments, ideal for sensitive mineral processing operations. - Welpac highlight:

Welpac offers customizable FIBCs tailored to your mining material and site requirements. Each fibc bulk bag is engineered to meet the required SWL, ensuring safety and compliance.

Cost Optimization: Bulk Bags vs Traditional Mining Containers

When it comes to mining logistics, cost efficiency is just as important as safety and reliability. Let’s compare FIBC bulk bags to traditional mining containers:

| Feature | FIBC Bulk Bags | Steel Bins/Drums |

| Price per unit | Cost-effective | Higher upfront cost |

| Transport & storage efficiency | Efficient bulk | Bulky, heavy, higher fuel cost |

| SWL | Up to 2,500kg | Varies, often lower |

| Handling | Easy with forklifts & cranes | Requires heavy machinery |

| Reusability | Reusable 5–10 times | Durable but less flexible |

| Risk of damage | Low with proper handling | Higher risk of dents & rupture |

Welpac highlight:

Polypropylene bulk bags from Welpac provide long-term savings, reduce material damage, and optimize supply chain efficiency. For mining companies buying in bulk, the difference in handling costs is significant.

Compliance & Safety in South African Mining Operations

Safety is non-negotiable in mining, and South African regulations are strict about packaging and transport:

- Key regulations:

FIBCs must adhere to safety standards, including top lift tests, SWL markings, and UV resistance for outdoor storage. - Traceability & certification:

Each fibc bulk bag should include traceability features to ensure compliance and avoid costly accidents. Uncertified bags increase the risk of rupture and operational hazards. - Guidelines for safe working:

Correct safe working load (SWL) labeling, safety factor, and strength testing are essential for transporting minerals and powders. - Welpac highlight:

Every high-quality FIBC bag from Welpac is designed to meet South African mining safety regulations, ensuring safe handling, transport, and storage compliance.

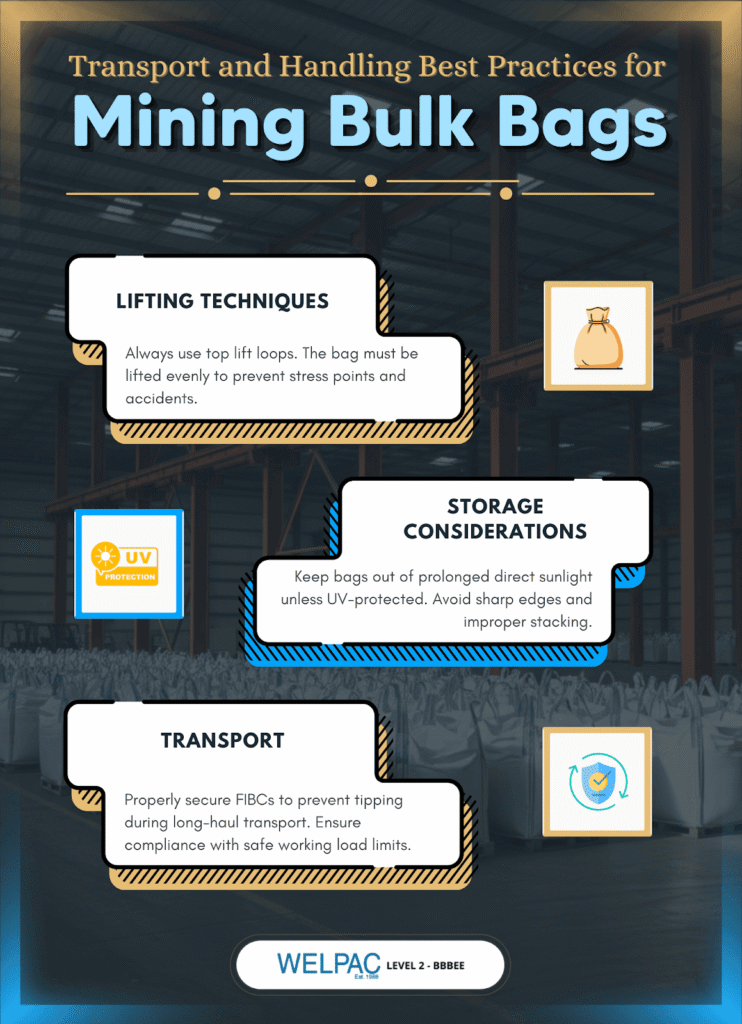

Transport & Handling Best Practices for Mining Bulk Bags

Case Studies: FIBC Bulk Bags in Mineral Processing Operations

Several mining companies in Gauteng and surrounding regions rely on Welpac’s FIBC bulk bags for mineral handling:

- Example 1:

A gold processing plant reduced container breakages by 40% after switching to high-quality FIBC bags with inner liners for fine powders. - Example 2:

A platinum mine improved supply chain efficiency using polypropylene bulk bags that are reusable, UV-resistant, and designed to meet SWL requirements. - Welpac highlight:

These bags work reliably under harsh conditions, with proven strength and reliability. Customers report cost savings, reduced downtime, and improved operational efficiency.

Best Fit: Why Choose Welpac for FIBC Bulk Bags in 2025

Welpac is a trusted bulk bag supplier in South Africa. Here’s why we’re the best fit:

- Over 25 years of industry experience.

- Extensive range of FIBC bulk bags, polypropylene bags, and customizable heavy-duty solutions.

- Compliance with all South African mining safety standards.

- Fast, reliable delivery across Johannesburg and Pretoria.

- Proven quality and performance with high-quality FIBC bags that meet the required SWL.

Quick comparison:

- Competitors may offer uncertified bags or limited SWL.

- Welpac ensures rigorous quality control, UV resistance, and top lift-tested loops.

- Customers gain traceability, safe handling, and efficient bulk storage.

Reputation:

- Featured in leading industry directories and media publications.

- Consistently positive reviews for reliability and service quality.

How to Buy & Source Bulk Bags

Ready to get started with FIBC bulk bags?

- Step 1: Identify your required SWL and material type (Type A, B, C, D).

- Step 2: Choose bags available with UV protection, spouts, or inner liners as needed.

- Step 3: Contact Welpac to buy bulk bags or browse bulk bags for sale in Gauteng.

- Step 4: Review FAQs, pricing guides, and testimonials for confidence in your purchase.

Welpac highlight:

We offer ready-to-buy polypropylene bulk bags, custom solutions, and efficient bulk handling support to keep your mining operations safe and cost-effective.

Safety, Reliability, and Cost Savings with Welpac

In 2025, choosing the right FIBC bulk bag is crucial for South African mining operations. From safe working load and material classification to compliance with safety standards, Welpac ensures your bulk bags are designed to handle heavy mining loads safely.

- Safe handling: Prevent costly accidents and ensure strength and reliability.

- Efficiency: Reduce transport costs and streamline loading and unloading.

- Compliance: Fully meet South African mining regulations with certified, traceable bulk bags.

Contact Welpac today to explore top-quality FIBC bulk bags and secure your mining operations in 2025. Don’t forget to check our full range of corrugated boxes, bubble wrap, labels, and strapping to optimize your packaging solutions.